- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

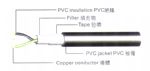

- PVC Flexible Power Cable

- Power Strip

- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- Power Strip

Electric flatiron with power cord easily wound up

Electric flatiron with power cord easily winded up includes a flatiron body which has a base plate and inside an electric heater which heats the base plate, the electric heater is connected with a power cord which extends out of the flatiron body. A hand grip portion is formed upon the flatiron body, the space between the hand grip portion and the flatiron body is used for winding up the power cord. The present invention breaks through the structural design of traditional electric flatiron and abandons the structure of traditional handle. The present invention create a creative design that provides a winding portion between the handle and the flatiron body, which ingeniously makes the handle and the winding up apparatus a integral part and fully utilizes the space between the handle and the flatiron body. Winding apparatus in this design may be easily used and hardly deteriorate.

Electric flatirons or electric irons are commonly used in people's daily lives, but there is a reoccurring problem of rolling up the power cord. In order to solve this problem, in the prior art, a winding apparatus is disposed at the rear of theelectric flatiron. This winding apparatus includes a winding box, the central portion of which is a winding shaft which is sleeved with a rotor plate used for winding the power cord.

Wherein, the rotor plate may rotate relatively to the winding shaft. In order to connect the electricity, the power cord must be connected to the heating component inside the electric flatiron through the rotor plate and winding shaft, whereinmany problems of the electric connection between components should be considered. In order to enable the winding shaft to roll back the power cord automatically, a coil spring which could force the rotor plate to rotate along the winding direction ofthe power cord should be set on the winding shaft. Meanwhile, a clip which could lock the power cord in pulled-out position should also be set, but these components may easily deteriorate when repeatedly used. When pulling the power cord out from thewinding apparatus, there should be enough force to overcome the force of the coil spring, and after being released from a locked position, the power cord immediately winds back under the force of the coil spring. The process of pulling out and windingback the power cord may easily cause related components to deteriorate.

Obviously, the existing winding apparatus of electric flatiron is complex, with high costs, and apt to break down.

In addition, the use of the winding apparatus makes the volume of the electric flatiron bigger. A handle is usually disposed upon the flatiron body, the space between the handle and the flatiron body is undesirably wasted. Therefore, electricflatiron of this kind is unreasonable in space design, which can not utilize space well.

The purpose of the present invention is to create an electric flatiron with a power cord easily wound up which corrects the unreasonable design of the prior art winding-up apparatus and the handle which make the electric flatiron have a complexstructure, high costs, a huge volume and be apt to break down.

The solution presented in this invention is: an electric flatiron with a power cord easily wound up, which comprises a flatiron body which has a base plate inside an electric heater which heats the base plate. The electric heater is connectedwith a power cord which extends out of the body. A hand grip portion is disposed upon the flatiron body, the space between the hand grip portion and the flatiron body could be used for winding up the power cord.

The above mentioned hand grip portion is disk-like body, which is connected to the flatiron body by a winding post, which has a bigger diameter in both ends and a smaller diameter in the middle. The outer surface of the winding post is a slickcovered surface. This surface, in company with the bottom surface of the hand grip portion of the top surface of the flatiron body, define the space used for winding up the power cord.

The top above mentioned flatiron body subsides slightly forming a sunken surface.

The related power cord extends out from the rear of the flatiron body, a clip used for lock the power cord is set on the top front portion of the flatiron body.

The related hand grip portion includes a temperature controlling knob, which controls the temperature of the electric heater. The temperature controlling knob embedded into the top portion of the hand grip portion.

One aspect of the present invention is an electric flatiron with a power cord easily wound up, which has a hand grip portion upon its body. In the approximate middle of the hand grip portion, there is a connecting portion connected to theflatiron body. Thus, there is no preformed space needed for fingers to cross through the above flatiron body, which helps the structural design.

Another aspect is an electric flatiron with a power cord easily wound up which has a hand grip portion. The hand grip portion may be designed in any suitable size and shape, e.g. like a mouse used with a computer.

- Contact Us

- Simen Twon,Yuyao City,Zhejiang,China,315472

- 86-0574-62162348

- 86-0574-62160100

- [email protected]

- hoobo.show1

- Terms and Conditions

- Privacy Statement

- Need help

- Home

- About us

- Products

- Download

- News

- Equipments

- Tech-Documnets

- Contact

- Products

- Power Cord

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- SUBSCRIBE

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- hoobo.show1

- 86-0574-62162348

- 86-0574-62162348